In the world of industrial mixing, the ribbon blender machine stands out for its effectiveness in mixing materials evenly and efficiently. From food processing to pharmaceutical industries, this versatile machine has become a staple in various production lines. But what exactly is a ribbon blender, how does it work, and what makes it so effective? This review explores these questions and more, offering a quick overview of the machine’s features, functions, and advantages.

Understanding the Ribbon Blender Machine

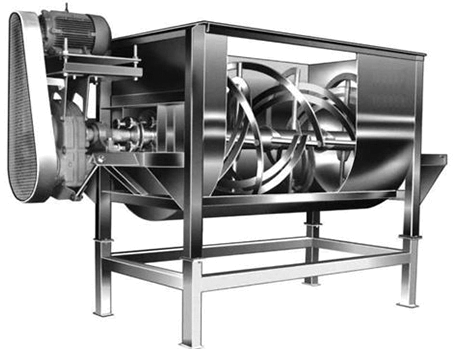

The ribbon blender machine is a type of industrial mixer known for its unique design, which consists of a long, horizontal trough and a central shaft with helical ribbons. These ribbons are typically made from high-grade stainless steel and are arranged in both outer and inner spirals. The outer spiral moves materials in one direction, while the inner spiral moves them in the opposite direction, creating a consistent blending effect.

Key Features of a Ribbon Blender Machine

-

Versatile Mixing Capability

The ribbon blender machine is highly adaptable, ideal for blending a wide range of materials, including powders, granules, and slurries. This versatility makes it invaluable across various industries. -

Efficient Mixing Mechanism

Its unique ribbon design ensures that materials are thoroughly mixed, promoting uniform distribution of ingredients. -

Cost-Effective and Low Maintenance

Ribbon blender machines require minimal maintenance and have a relatively low cost of ownership, making them a popular choice for businesses.

How Does a Ribbon Blender Machine Work?

The functionality of a ribbon blender machine is straightforward. Material is loaded into the blender’s horizontal trough, where the helical ribbons attached to a rotating shaft turn and agitate the contents. The counter-flowing ribbons create a pattern of circulation within the trough, moving materials both radially and laterally. This motion ensures an even distribution and a highly efficient blending of ingredients.

- Outer Ribbon: Pushes materials towards the center.

- Inner Ribbon: Moves materials toward the ends, facilitating complete mixing.

Applications of Ribbon Blender Machines

Ribbon blenders are widely used across industries due to their adaptability. Here’s where they make the most impact:

- Food Processing Industry: From blending dry spices to mixing baking ingredients, ribbon blenders ensure homogenous mixing essential for food safety and quality.

- Pharmaceuticals: The machine’s ability to mix powder uniformly is critical in the production of pharmaceutical products, where consistent ingredient distribution is necessary.

- Chemical Industry: In the production of paints, coatings, and adhesives, the ribbon blender machine is essential for blending chemicals thoroughly.

Advantages of Using a Ribbon Blender Machine

The ribbon blender machine has multiple benefits that contribute to its popularity:

-

Consistent and Uniform Mixing

The machine’s design promotes a thorough, even mix, ensuring that all materials are properly blended. -

Scalability

Ribbon blenders are available in various sizes, from small-scale units for R&D to large industrial models for high-capacity production. -

Energy Efficiency

With a low energy requirement, the ribbon blender is economical to operate, even for long production runs. -

Ease of Cleaning and Maintenance

The simplicity of the ribbon blender’s design allows for easy cleaning, a crucial factor in industries with strict hygiene standards.

A Fact about Ribbon Blender Machines

Did you know? According to recent studies, ribbon blender machines can achieve up to 99% homogeneity in just a few minutes of mixing, making them one of the most efficient options for industrial blending.

Choosing the Right Ribbon Blender Machine for Your Needs

When choosing a ribbon blender machine, consider these factors:

- Capacity Requirements: Ensure the blender’s capacity aligns with your production scale.

- Material Characteristics: Choose a machine with the appropriate ribbon design and motor strength based on your material’s density and texture.

- Cleaning and Maintenance Needs: For food or pharmaceutical applications, prioritize machines with easy access for cleaning.

Common Industries Using Ribbon Blender Machines

-

Agriculture

The machine is ideal for mixing feed, fertilizers, and other agricultural products. -

Plastics

Used in blending plastic resins and additives, contributing to uniform production quality. -

Cosmetics

In cosmetic manufacturing, ribbon blenders mix powders and creams to ensure product consistency.

Conclusion

The ribbon blender machine is an exceptional tool that provides efficient and uniform blending for a variety of materials. Its unique design, combining inner and outer ribbons, ensures even mixing, making it indispensable across numerous industries. Whether for food processing, pharmaceuticals, or chemicals, the ribbon blender machine stands out as a reliable and cost-effective solution. As industries continue to grow and innovate, the demand for reliable mixing equipment like ribbon blenders will only increase.

Buraq Engineering specializes in providing top-quality ribbon blender machines designed to meet the diverse needs of industries like food processing, pharmaceuticals, and chemicals. Known for their efficiency and durability, Buraq Engineering’s ribbon blenders ensure consistent, uniform mixing, enabling businesses to achieve high-quality results. With a focus on performance and reliability, Buraq Engineering has built a reputation as a trusted ribbon blender machine provider worldwide.