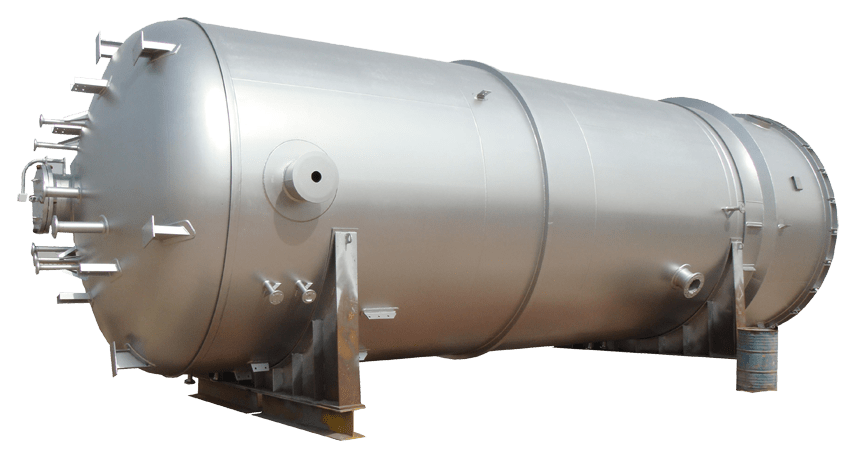

The pressure vessel market is on a trajectory of significant growth, driven by increased demand across industries like oil and gas, chemical processing, and power generation. By 2025, experts anticipate that the market will reach new heights due to advancements in technology, higher safety standards, and an expanding global industrial base. As pressure vessel manufacturers continue to innovate, the industry is poised to make substantial contributions to both infrastructure and environmental safety.

Introduction

The global pressure vessel market is projected to grow substantially by 2025. Pressure vessels, essential for storing and transferring high-pressure gases and liquids, are used in several critical industries. These vessels are designed with the highest standards of safety and efficiency, as any failure could lead to catastrophic consequences. For this reason, pressure vessel manufacturers are focusing on creating products that are both durable and compliant with stringent safety standards. In this article, we’ll explore the market’s expected growth, the main drivers of demand, and the future landscape of the pressure vessel industry.

Current Market Overview

The demand for pressure vessels is rapidly expanding due to their wide application across several sectors:

- Oil and Gas: Pressure vessels store and transport flammable gases and liquids, ensuring safe operations.

- Chemical Processing: The chemical industry relies on pressure vessels to handle hazardous materials.

- Power Generation: Pressure vessels play a critical role in steam production and energy storage, particularly in nuclear and thermal plants.

A fact worth noting is that according to recent studies, the global pressure vessel market size was valued at approximately $42 billion in 2021 and is expected to grow at a compound annual growth rate (CAGR) of about 4.3% from 2022 to 2025.

Key Growth Drivers for Pressure Vessel Market

1. Industrial Expansion

- Industrial growth, especially in developing economies, is one of the primary drivers for pressure vessel manufacturers.

- Countries in Asia-Pacific and the Middle East are investing in expanding their industrial sectors, creating a demand for reliable pressure vessels.

2. Technological Advancements

- The use of composite materials and better welding techniques is allowing manufacturers to create stronger, more efficient pressure vessels.

- Advancements in non-destructive testing (NDT) help ensure the quality of materials and structural integrity of vessels, improving overall safety.

3. Environmental Standards and Compliance

- Increasing environmental regulations are pushing industries to upgrade to pressure vessels that are compliant with safety and emission standards.

- Pressure vessel manufacturers are prioritizing eco-friendly materials and designs to meet regulatory compliance.

Latest Trends in Pressure Vessel Manufacturing

Advanced Material Usage

- High-strength steel, composites, and carbon fiber are being used to improve pressure vessel durability and reduce weight.

- These materials help vessels endure extreme temperatures and pressures, making them ideal for advanced applications.

IoT Integration for Monitoring

- Internet of Things (IoT) sensors are being incorporated into modern pressure vessels.

- This enables real-time monitoring of temperature, pressure, and structural integrity, which can preemptively indicate any issues.

3D Printing in Manufacturing

- 3D printing technology is allowing for more complex and precise vessel designs.

- This trend is making it feasible to customize vessels according to specific industrial needs.

Pressure Vessel Market Segments and Key Players

Market Segmentation

- Material Type: Steel alloys, composites, and other metals.

- Application: Segmented into power generation, chemical, oil and gas, and food & beverage.

- Type: Boiler, reactor, separator, and storage vessels.

Key Pressure Vessel Manufacturers Several key players are contributing significantly to the global pressure vessel market:

- General Electric: Known for supplying pressure vessels for power plants globally.

- Babcock & Wilcox: Specializes in manufacturing boilers and power generation equipment.

- Doosan Heavy Industries: A prominent player in nuclear and thermal power plant pressure vessels.

Conclusion

In summary, the pressure vessel market is expected to see steady growth by 2025, with a significant contribution from pressure vessel manufacturers worldwide. Technological innovations and stringent regulatory requirements will continue to shape the market, encouraging safer and more efficient designs. As industries continue to expand and environmental standards tighten, demand for high-quality pressure vessels is anticipated to remain strong.

Pressure vessel manufacturers have a vital role in supporting industrial growth and ensuring safety across applications. With the continued push for high standards and technological progress, the future of the pressure vessel market is promising.

Buraq Engineering is a leading pressure vessel manufacturer, known for providing high-quality, durable vessels tailored to meet the diverse needs of industries worldwide. Their advanced manufacturing techniques and strict adherence to safety standards ensure that each pressure vessel is reliable and efficient, even in the most demanding environments. By prioritizing innovation and compliance, Buraq Engineering consistently delivers products that exceed industry expectations, making them a trusted choice for companies seeking top-tier pressure vessel solutions.