Estimating CNC machining costs accurately is crucial for managing budgets and ensuring project feasibility, especially for industries like aerospace, automotive, and electronics, where precision and cost-efficiency are paramount. CNC machining costs encompass various factors, including material selection, machining complexity, and production time. In this guide, we will cover essential steps to accurately estimate CNC machining costs, so you can make informed decisions and keep your project within budget.

Understanding the Primary Factors in CNC Machining Costs

When calculating CNC machining costs, several primary factors play a vital role, each impacting the final expense of your project. Material costs, for instance, vary widely depending on the type and grade chosen, with metals like titanium and stainless steel generally costing more than aluminum or plastics. The complexity of the design is another key factor. Intricate designs with tight tolerances or unique features typically require more machining time, which raises costs.

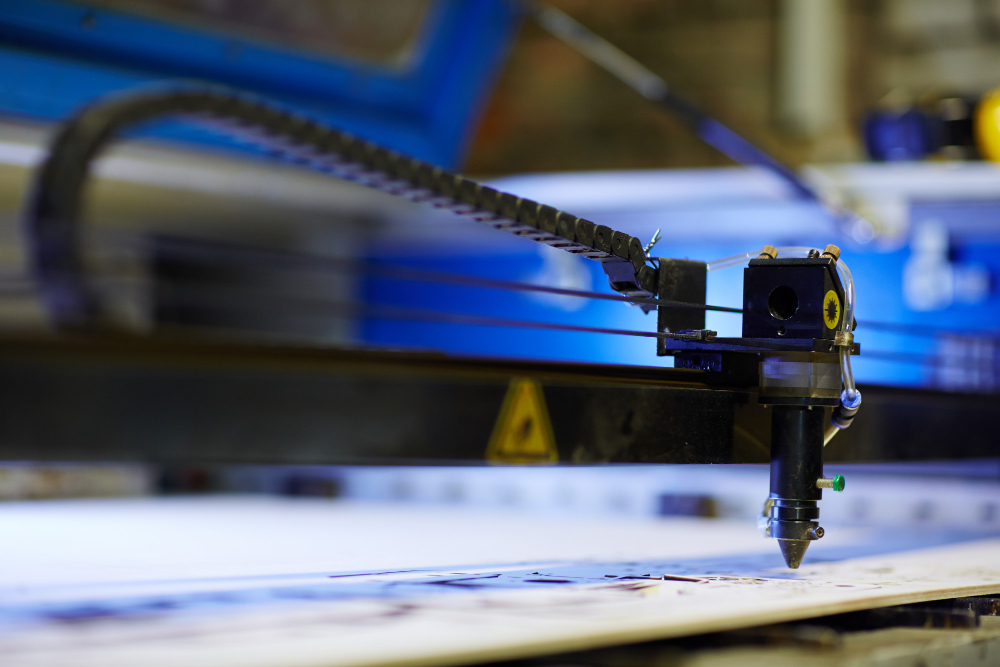

The cost of CNC machining also depends on the equipment and technology used, as advanced machinery can yield better precision but comes at a higher operational cost. Labor costs also affect the total, depending on the skill level required for the project. By understanding these fundamental factors, you can begin to develop a more accurate estimate for your CNC machining costs and potentially identify areas for cost savings.

Choosing the Right Materials to Control CNC Machining Costs

Material selection is a significant contributor to CNC machining costs, as each material requires different tools and techniques. Metals like titanium or hardened steel require higher cutting forces, specialized tooling, and often slower speeds, all of which can increase costs. In contrast, materials like aluminum or certain plastics are easier to machine, reducing machining time and tool wear. When choosing materials, balancing performance requirements with budget constraints is essential for cost-effective CNC machining.

For cost control, consider alternative materials that still meet your project specifications. For instance, if weight and corrosion resistance are critical, aluminum may be a more affordable choice than stainless steel. Additionally, the shape and size of the material affect CNC machining costs, with larger or oddly-shaped blocks potentially increasing material wastage and, subsequently, costs. Selecting the right material early in the planning stage can have a substantial impact on overall CNC machining expenses.

Assessing Design Complexity and Its Impact on CNC Machining Costs

The complexity of the part’s design directly affects CNC machining costs. Simple designs with fewer features, larger tolerances, and fewer axes for machining are generally quicker and more cost-effective to produce. However, intricate designs that require multiple setups, tight tolerances, and complex geometries will increase machining time, labor, and even equipment wear, leading to higher costs.

To manage costs, simplify the design where possible. For instance, avoid sharp corners and undercuts that require additional tool changes or custom tooling. Design for manufacturability (DFM) principles can help identify features that complicate machining and increase costs. By minimizing unnecessary complexity in the design, you can reduce CNC machining costs without compromising the quality or functionality of the part.

Calculating Production Time to Accurately Estimate CNC Machining Costs

Production time is a critical factor in determining CNC machining costs, as most CNC machines operate on an hourly rate. The machining time depends on the part’s complexity, the required precision, and the chosen material. Harder materials and complex geometries typically extend machining time, thus increasing the cost. Additionally, the type of CNC machine affects production time; multi-axis machines, for example, can perform complex cuts faster but at a higher hourly rate.

To estimate CNC machining costs accurately, analyze the estimated machining time based on your part’s specifications. Many manufacturers provide rate estimates based on their machines, so it’s helpful to gather quotes from several suppliers. If the part requires multiple passes or finishing processes, these should be factored into the production time estimate. Analyzing production time early can help prevent unexpected expenses and ensure that the project stays within budget.

Factoring in Post-Processing and Finishing for Comprehensive CNC Machining Costs

In addition to material, design, and production time, post-processing and finishing requirements significantly impact CNC machining costs. Finishes such as polishing, anodizing, and powder coating add to the overall project expenses. Some projects may require specific post-machining treatments for enhanced durability, appearance, or functionality, depending on the intended use of the part. Each finishing process has its own cost and may require additional setup or specialized equipment.

By understanding the specific finishing needs of your project, you can better estimate total CNC machining costs. For instance, if a high-quality finish is necessary, budget accordingly, and ensure you factor these costs into the overall estimate. In cases where finishing can be simplified without compromising quality, consider alternative finishes to reduce expenses. Factoring in post-processing from the outset allows for a more accurate and realistic estimate of CNC machining costs, helping you make informed decisions.

By considering these key aspects—material choice, design complexity, production time, and finishing requirements—you can accurately estimate CNC machining costs for your project. Proper planning and budgeting will not only help manage expenses but also ensure the project remains viable and successful.