The global encoder market size attained a value of nearly USD 2.42 billion in 2023. The market is further expected to grow in the forecast period of 2024-2032 at a CAGR of 8% to reach nearly USD 4.83 billion by 2032. Encoders, as vital components in automation, robotics, and electronics, are gaining traction across diverse industries. This post will provide an in-depth analysis of the encoder market, including its segmentation by type, technology, end use, regional trends, and key market dynamics that will shape its growth in the coming decade.

Market Segmentation

The global encoder market is diverse, with various types, technologies, and applications. Understanding the market’s segmentation helps in recognizing where the most significant opportunities lie.

By Type

Encoders can be broadly classified into two main types: rotary and linear encoders, each serving distinct applications and industries.

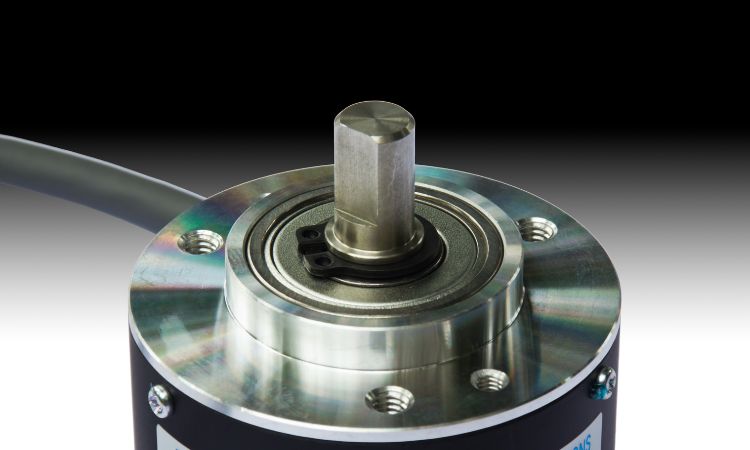

Rotary Encoders

Rotary encoders are used to measure the rotation of a shaft or axle and convert it into an electrical signal. They are essential in applications where precise control of rotational movement is needed, such as in industrial machinery, robotics, and automation systems. As industries continue to embrace automation and robotics, the demand for rotary encoders is anticipated to see consistent growth. In fact, rotary encoders are projected to hold the largest market share in the coming years, driven by their widespread use in manufacturing and automotive industries.

Linear Encoders

Linear encoders, on the other hand, measure the linear position of a moving object and provide feedback on its exact location. These encoders are particularly useful in applications such as CNC machines, semiconductor manufacturing, and optical devices. While linear encoders hold a smaller market share compared to rotary encoders, they are poised for growth as precision in linear motion becomes increasingly critical in various sectors, including electronics and medical devices.

By Technology

The encoder market is also segmented based on the technology used to capture motion. Each technology offers distinct advantages depending on the specific requirements of an application.

Optical Encoders

Optical encoders use light and photodetectors to sense the position of a rotating or linear object. They are known for their high accuracy, reliability, and performance in clean environments. Optical encoders dominate the market due to their precision and widespread use in applications requiring detailed motion sensing, including robotics, consumer electronics, and industrial automation.

Magnetic Encoders

Magnetic encoders, which rely on magnetic fields to determine position, offer robust performance in harsh environments, making them ideal for industries such as automotive, aerospace, and heavy machinery. While magnetic encoders may not match optical encoders in terms of precision, they provide a more cost-effective and durable solution in many industrial applications.

Photoelectric Encoders

Photoelectric encoders operate using light sensors and are similar to optical encoders but with specific use cases that suit particular industrial and automotive applications. These encoders offer high durability and are used in applications like material handling, packaging, and automotive systems, where long-lasting performance under varying conditions is crucial.

Other Technologies

Other encoder technologies, such as capacitive and inductive encoders, also play a role in the market, though they are less prevalent compared to the primary types mentioned above. These encoders typically find niche applications where cost efficiency or resistance to specific environmental factors is required.

By End Use Industry

Encoders find applications across various industries, and their demand is heavily influenced by trends in automation, digitalization, and manufacturing precision.

Automotive

In the automotive sector, encoders are essential for controlling and monitoring the position of various components such as steering, throttle, and transmission. The rise of electric vehicles (EVs) and autonomous driving technologies is expected to drive substantial demand for encoders in this sector. The growing push towards automation and electrification of vehicles will further enhance the demand for encoders, particularly in motion control systems and vehicle safety features.

Electronics

The electronics industry is another key driver of encoder demand. With the increasing need for automation and the rapid advancement of technologies such as robotics and consumer electronics, encoders are integral in systems that require precise motion control. From smart devices to industrial robots, encoders enable high-performance and efficiency in manufacturing processes, positioning them as critical components in the electronics sector.

Textile and Printing Machinery

In textile and printing machinery, encoders are used for controlling the position of fabric or paper, ensuring accuracy in cutting, printing, and other processes. With the continuous advancements in textile and print technology, particularly in digital printing, encoders are becoming increasingly important for achieving higher efficiency and reducing production costs.

Industrial

The industrial sector remains the largest consumer of encoders, particularly in automation, CNC machinery, and robotics. As industries around the world shift toward Industry 4.0, the demand for encoders is set to grow as they are fundamental in providing feedback for control systems and improving operational efficiency.

Pharmaceuticals

In the pharmaceutical industry, where precision and accuracy are essential for manufacturing drugs, encoders play a critical role in the operation of automated systems, such as those used in packaging and quality control. Regulatory standards also demand high accuracy and repeatability, which encoders help to achieve, making them a vital component in pharmaceutical manufacturing processes.

By Region

Encoders are used worldwide, and regional differences in industrialization, technological development, and demand for automation influence the market dynamics.

North America

North America, particularly the United States, is one of the largest markets for encoders due to the high level of automation across industries such as automotive, electronics, and pharmaceuticals. The adoption of Industry 4.0 technologies is accelerating encoder demand, and the increasing focus on smart manufacturing will continue to drive growth in this region.

Europe

Europe is home to some of the world’s largest automotive manufacturers, which drives the demand for encoders in the region. The push towards electrification and autonomous vehicles in Europe further strengthens this trend. Additionally, Europe’s emphasis on sustainable and energy-efficient manufacturing practices positions encoders as crucial components in achieving these goals.

Asia-Pacific

Asia-Pacific is expected to see the fastest growth in the global encoder market. The region’s rapid industrialization, particularly in countries like China, India, and Japan, fuels demand for encoders in sectors like automotive, electronics, and industrial automation. The expansion of smart factories and the rise of manufacturing hubs in the region will continue to drive encoder adoption.

Latin America and Middle East & Africa

Both Latin America and the Middle East & Africa are emerging markets for encoders, with increasing investments in industrial infrastructure, energy, and manufacturing. As these regions continue to modernize, the adoption of automation technologies, including encoders, is set to grow.

Market Dynamics

Drivers

The encoder market is experiencing substantial growth due to several key drivers:

- Increasing Automation: As industries embrace automation to improve efficiency and reduce labor costs, the demand for encoders as essential components of control systems continues to rise.

- Technological Advancements: Innovations in encoder technology, such as enhanced accuracy, wireless communication, and miniaturization, are expanding their applications across industries.

- Rise of Electric Vehicles: The automotive industry’s shift toward electric and autonomous vehicles is driving demand for encoders for precision control in various vehicle systems.

Restraints

Despite its growth, the encoder market faces some challenges:

- High Cost of Advanced Systems: The cost of advanced encoder technologies, particularly optical and high-resolution encoders, can be a barrier for smaller manufacturers.

- Environmental Factors: Encoders used in harsh environments may face technical challenges such as interference, temperature fluctuations, and mechanical wear.

Opportunities

There are several emerging opportunities in the market:

- Growth in Renewable Energy: The increasing demand for renewable energy sources, particularly wind and solar energy, presents opportunities for encoders in energy production systems.

- Advances in AI and IoT: The integration of encoders with AI and IoT technologies offers exciting possibilities for automation and smart manufacturing.